The

Barbara Kerr Solar Wall Oven Do-It-Yourself

Guidelines

By

Jim Scott, Kerr-Cole Sustainable Living Center, scottjl_79@hotmail.com

1.

Introduction:

This

publication describes the considerations for designing and building a

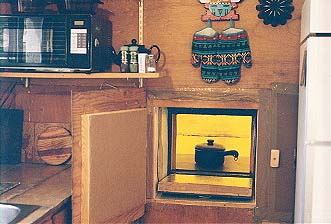

slant-faced, reflectorless, through-the-wall solar box cooker, as depicted on

the Solar Cooking Archives web site:

http://solarcooking.wikia.com/wiki/Solar_Wall_Oven

This

image shows such a cooker with slanted front and rear wall segments. The

Kerr-Cole designs have dispensed with these angled panels in the interests of

easier construction and a roomier floor space (at the cost of slightly slower

cooking). This version is shown on the pages:

This

publication also covers the issues involved in installing the cooker in the wall

of a building. It does not provide detailed construction plans either for the

cooker or its installation. This leaves wide latitude for selection of materials

that are locally available and/or compatible with the type of home construction.

Throughout we assume a northern hemisphere location. Down Under readers will be

obliged to substitute “north” wherever “south” is encountered. Solar

Wall Ovens are available from the Kerr-Cole Center as completed units. Contact

us at for kerrcole@frontiernet.net

for price and delivery.

The

Solar Wall Oven also works very well as a freestanding cooker that can be

transported from site to site. When freestanding it can be aimed to keep it

pointed in the direction of the sun, which lengthens the number of hours it can

cook each day. When freestanding, this cooker gives excellent results both in

temperate and equatorial latitudes.

However

it is used, the rear-opening door of this design is a major convenience compared

to conventional top-opening cookers. We drill a hole in the bottom center of the

cooker that can mate with a small rod projecting from the top center of a

55-gallon drum. The oven is placed atop the drum such that it pivots on the rod.

It helps to soap the drum rim so that the cooker rotates easily. The drum is

half filled with water to keep the whole works from blowing over. In temperate

latitudes the cooker may be used freestanding during construction and then

attached when the house is ready.

Or, for

maximum convenience, one may wish have available for use both a freestanding and

an attached cooker.

2.

A Comment on Reflectors:

Although the basic design

concept of the Solar Wall Oven is to eliminate the need for reflectors,

nonetheless it’s usefulness can be enhanced if provision is made to employ

reflectors some of the time. This is true both for freestanding and

through-the-wall use of the cooker. The use of reflectors is an important topic

with a number of considerations pro and con. We will skip over these issues for

the time being and take up the matter later on in Section 12. For now we will

confine our attention to the simpler, basic, reflectorless design. Suffice it to

note that to date Barbara Kerr has used a wall mounted, slant-faced, box cooker

to do the bulk of her solar cooking in Arizona (35 degrees north latitude) over

the last 15 years and hers does not turn, nor does it have a reflector. Barbara

states, “It cooks all day without further attention. Three steps. Put the food

in, leave it alone, remove and eat.”

Barbara continues, “In

addition to requiring additional construction materials and labor, the need to

go outside to adjust reflectors would require attention throughout the day, as

well as eliminate its use for mobility restricted people. It also would make it

difficult to use on upper floors.” As well as sometimes using a freestanding

Solar Wall Oven, Barbara occasionally uses an outdoor freestanding cooker of a

different design, such as a SOS Sport, (www.solarovens.org) to handle the need to

aim an oven for cooking early or late in the day. The Sport has an optional

reflector that can be attached to enhance heat collection in marginal sun

conditions. She also may use a panel type cooker such as the CooKit, Solar Panel

Cooker or Reflective Open Box Cooker to capture low angle sunlight. See:

http://www.solarcooking.org/plans.htm#panel-style

3.

Site:

Slant-faced, reflectorless,

cookers mounted in a wall are suitable for temperate latitudes only. In tropical

regions, the sun will be on opposite sides of the home summer and winter,

progressively restricting the seasons of usefulness of a fixed mounted cooker

the closer to the equator it is installed.

In

northern temperate regions, the structure must have a south-facing wall

available for installing the cooker. True due south orientation is preferred for

the cooker. A wall-mounted cooker cannot be turned to follow the sun. A cooker

aimed SE or SW will limit afternoon or forenoon cooking respectively. A true

south cooker (without reflectors) will be effective from about 9 AM to 3 PM

solar time from mid February to the beginning of November (northern hemisphere).

It will still work for more easily cooked foods for the balance of the year from

about 10 AM to 2 PM.

The wall must be relatively

free of shading by nearby structures, geological features and trees for a large

percentage of the day throughout the seasons. The roof overhang may partially

shade the cooker in some seasons, hindering cooking, particularly in the

latitudes nearer the tropics. A detailed treatment of this topic is given in

Section 11.

The cooker is best suited for

homes designed with solar cooking in mind. It will work in existing homes only

if a suitable south wall location is available. Installation through a window

might be a practical and simple way to retrofit a Solar Wall Oven. Although we

have not tried this ourselves, it seems that if it were placed freestanding on a

shelf outside the window, it could be aimed from inside to follow the sun.

Optional auxiliary reflectors might be managed by reaching out the window, and

the cooker might be slid in and out for loading and unloading. If glazed with

lightweight plastic rather than glass, the cooker might even be moved during the

day to take advantage of which window is getting the sunlight.

The geographical restriction to the temperate zone installation would be much less of a consideration for dome shaped structures, or vault shaped structures with the long axis oriented east-west, than it is for vertical walled structures. There will be a much lower tendency for the building to shade the glazing when the sun passes on the “wrong side” of the house in the summer. In the tropics one should choose the south side if located north of the equator and the north side if located south of the equator. The glazing angle should be flatter than the 20 to 30 degrees suggested for the higher latitudes, as the sun will be generally high in the sky all year. Indeed, at the equator, horizontal glazing would be best, and one may chose to install the cooker on either the north or south side with equal justification. For a dome near the equator, any orientation will suffice, even due east or due west – as these orientations would sacrifice heat collection due to shading by the house only when the sun is near the horizon on the opposite side of the house.

4.

Cost and Difficulty of Construction:

Building

a durable, effective, slant-faced, through-the-wall, box cooker to attach to a

house is not as easy or as inexpensive as one might suppose.

There are problems with angled construction, providing a door, proper

sealing and obtaining proper materials – particularly the glazing. The

materials inside and outside the oven variously must withstand for the life of

the cooker (potentially 50 years): 350 deg F, high humidity, UV radiation,

freezing, impact, sandstorms (Arizona), moisture infiltration, abrasion by

cooking vessels and food spillage while achieving good cooking capability,

attractive appearance, food safety, easy maintenance and cleanablity. For

example, while there exist many inexpensive choices for insulating material,

these generally come at the cost of complex construction to contain them,

protect them, and keep them dry. Another example: although strong, available,

easy to fabricate into the desired pieces for construction and easily fastened

together, wood will not withstand intense solar radiation on hot exposed

surfaces, such as the rim of the cooker where the glazing is attached. Left continuously exposed to the weather, it shrinks, warps

and splits. It requires yearly repainting with marine varnish to prevent

degradation. As for glazing, you get a choice of cheap and not durable plastic;

high-grade, high temperature solar plastic (difficult to find or downright

unobtainable); or tempered glass (good looking and very durable but expensive

and heavy). Figure it may take a week of full days (assuming you do not have

access to a well equipped wood and/or metal shop), plus $150 and up in

materials, to build a glass glazed, plywood box cooker.

With this discussion of

suitable materials, one should keep in mind that Barbara Kerr discovered nearly

30 years ago that highly effective box cookers can be made out of cardboard,

wood glue, aluminum foil and window glass or plastic film. On the Solar Cooking Archives

http://www.solarcooking.org/plans/default.htm#box-style

web site and you will find plans for a number of cookers built this way.

The drawback is that typical cardboard cookers are not durable enough to be

built into a house. An exception to this might be the very robust, plastic

covered, cardboard cookers being made in Africa, as described in the book Appropriate

Paper-Based Technology (APT, A Manual).

2

Note that Barbara’s present

Solar Wall Oven, built with a plywood exterior, crushed newspaper insulation,

aluminum foil covered corrugated cardboard inner walls and tempered glass

glazing - put together with lots of silicone sealant - has remained in daily use

for many years. The outside does require repainting and re-caulking

occasionally. Freestanding Patio Oven cookers, built with these same materials,

have remained in continuous use for 25 years. They are still in good condition.

Ours has remained outdoors for this long, summer and winter in our desert

climate, without ill effect.

Builders constructing homes

of insulating alternative materials such as papercrete, strawbale, rastra block

and the like should consider incorporating wall ovens made of the same materials

as an integral component of the structure. This would simplify construction,

lower costs, allow for structural integrity and good environmental sealing, and

make it possible to aesthetically sculpt the cooker to blend in with the

exterior architecture. Be advised that this approach is conjectural. To date we

have no reports of cookers made this way – and there are concerns that the

higher thermal mass of these materials may impede cooking to a significant

degree. Therefore use of these materials would have to be considered

experimental until proven in practice. Our

Center plans to evaluate these materials soon. Contact us and we will share what

we have found out.

Another

possible low cost material that would require little in the way of tools or

experience in building things is paper mache’, which is an insulating

structural material. We have not experimented with paper mache’ cookers

ourselves yet to find out, for instance, if it presents thermal mass problems.

It is said to be easy to form in place and mold around the glazing, oven door

and house attachment, making it a good candidate for retrofitting into existing

structures. If coated on the outside with water seal and regular house paint, it

should be quite weather resistant. It also would be readily repairable using

paper mache’ “mortar”. If you use regular glass, and it eventually breaks,

paper mache’ could be easily cut to remove and replace the glass. The inside

can be moisture sealed with glued on aluminum foil or black BBQ paint. If you

have the time, but not much money, the paper mache’ solar wall oven might be

just the ticket, particularly if your carpentry skills are not the greatest. The

following link shows an African group that has started a business making things,

including solar cookers, out of paper mache:

5.

The Door:

The

door generally will be the biggest problem in construction. Beware of metal

doorframes or a metal rim on the door itself. Even thin metal foil will rob a

surprising amount of heat by conduction from inside to outside. Gaps around the

door allow air infiltration and therefore can cause heat loss. In calm air the

loss is surprisingly small even for a poorly fitting door. For a

through-the-wall installation with an otherwise tight oven construction, a

loosely fit door, say with 1/16 inch gaps all around will loose little heat. But

outdoors on a windy day the losses for a freestanding oven can be significant

indeed, leading to concern for achieving a tightly fitting door for this use.

Since

the door is in the rear of the solar wall oven, it is not subject to intense

solar radiation, even in freestanding use, making the use of wood feasible.

However wood door parts expand when wet from cooking vapors; the door will stick

unless constructed loosely. A tapered jamb “plug” door helps, but does not

solve the problem of achieving a tight fit while avoiding sticking. We have had

reasonable luck using a wood framed tapered door with a formed-in-place silicone

gasket incorporated in the doorjamb. The silicone is plastered around the

loosely fitting jamb and covered with waxed paper. Then the door is closed while

the silicone is uncured, forcing it to conform to the door. The results are not

necessarily pretty, and it will take days before the silicone has cured

enough to open the door without tearing the gasket, but it does work. A

commercial silicone high temperature gasket would quite likely give more

professional looking results.

Another way to cut down on air infiltration is to provide external flanges, perhaps an inch in width, attached to the outside of the door around the sides and top. We have also used 1 inch flanges mounted around the inside of the doorframe to good effect, but this cuts down the size of the opening a bit. Both inside and outside flanges have been found to be effective in minimizing air infiltration. It is suggested that flanges be used if the door does not fit tightly and the oven is to be used freestanding. An outside flanged door is shown at Dr. Paul Funk's SWO in Mexico

The door (as well as the rest

of the interior of the cooker) must be made of non-toxic materials that do not

out-gas when hot. In freestanding use the door must be quite durable. People

will tend to lift the cooker using the door handle as a grip. Worse, the door

will be subject to very heavy stress if it is allowed to flop down with the rear

of the cooker near the edge of a table, as a severe lever action will occur.

Rigid metal hinges usually result in alignment and/or attachment problems. The

writer prefers to hinge the door with cloth, such as cut from an old polyester

pant leg, impregnated with silicone. Two layers are used, one on the inside and

one on the outside of the hinge line so that the material resists peeling in

either direction. This is not the best looking solution, but it certainly works

well in practice.

Another hinge material that

works well is 1-inch web strapping. Three strips will suffice. Install ¼ -inch

grommets in the strap at attachment points, then install using pop rivets or

screws as appropriate.

Venting:

When an oven is tightly constructed all over, another problem often surfaces.

Moisture from the food condenses on the undersurface of the glazing, blocking

sunlight from entering the cooker and reducing the cooking capacity. One way to

handle this problem is to provide two holes through the door about 3/4 inch in

diameter. One may use 3/4 inch plastic hot water pipe to line the holes. One

hole should be down low. The other should be up high. The upper hole should be

closable to prevent unnecessary air circulation when the oven is dry (a plug of

cloth or cotton would do it). The lower hole may be left open unless there are

rodent and insect concerns. Another

design uses a single slat pivoted at a point half way between holes placed one

above the other at the top and bottom of the door. Rotating the slat opens both

holes variably to the same degree simultaneously. Yet another method employs a

Velcro hole cover movable to control the degree of venting. One normally keeps

the vents closed, opening them only to the degree needed to keep the oven from

steaming up.

Door

width: The wider the better. We suggest 26.5 inches to clear a full-size 26 by

18 inch baker’s tray slid in sideways. A tray this size allows cookware placed

on it to be moved in and out en masse. With a door this wide, the upper

doorjamb must be configured to carry a major portion of the structural load

across the back of the cooker. A 26.5-inch door will open into the space between

three studs on 16-inch centers by cutting out the center vertical stud. This

produces an opening 30.5 inches in width, providing enough room at either side

(a couple of inches) for external door flanges and for the construction of the

pass-through tunnel walls. This width is our preference, although narrower doors

have been used and may be preferable on some houses, depending on construction

details and the layout of the kitchen.

The door usually is

configured to open downward or to the side. The down opening door is perhaps

best, particularly if it is hinged at the bottom rear exterior corner of the

cooker so that the inside surface of the door in the open position lies exactly

at the level of the oven floor. This facilitates sliding cookware in and out

over the open door, easily and without spillage. The upper surface should be

covered with sheet metal (black or shiny) to combat abrasion and wear. Hard

anodized aluminum is OK, but it will scratch. Polished stainless steel will be

more durable. An upward opening door tends to be awkward and inconvenient unless

some means is provided to hold it in the open position when cookware is being

put or removed from the oven. For a through-the-wall installation with an upward

opening door, a counterweighted cable or cord running from the bottom edge of

the door exterior, up over the top of the cooker and down in front of the cooker

does the trick, as the door will remain in place when moved either to the open

or closed position.

The

door probably will need some sort of latch or catch to hold it completely

closed, particularly for an outdoor cooker. It should be operable one handed so

the cook can open or close the door quickly and surely with a pot in the other

hand. A Velcro strip attached to the top of the door makes a good latch for a

freestanding cooker if configured as a strap handle to peel open. The free end

of the strap should wrap over the top of the cooker a short distance for secure

fastening. The strap does not impede the full opening of the door to lie flat

and level. Since the outdoor cooker will have the rear of the cooker exposed to

sunlight, the Velcro will require occasional replacement. For better durability,

check out your local garden supply merchant for the sun resistant Velcro straps

used for tying up plants.

For through-the-wall mounted cookers, a short, pivoted slat of wood installed on the top center of the oven doorframe has been found to be quite practical as a latch.

6.

Insulation:

Allow

no thermally conductive sheet metal or metal foil paths from interior

metal surfaces to exterior metal surfaces anywhere, such as around the top where

the glazing meets the rim. The heat loss via such a path can be significant.

The

walls, door and floor should employ at least R-8 insulation, or close to it -

the higher, the better.

For most materials 2 inches

thick insulation will be sufficient. Often 4 inches will give somewhat better

performance, but heat loss through the walls is not of over riding concern.

A high-performance insulation

such as Dow Thermax polyisocyanurate foam board (the stuff with metal foil on

both sides) requires only one inch. Do not use the commonly available Dow Tuff-R

polyisocyanurate foam board (the stuff with black plastic on one side). It will

not take the heat due to lack of fiber reinforcement. Be careful, some stores

incorrectly call this stuff “Thermax”. It is not Thermax.

A

less appreciated consideration is the thermal mass of the interior walls that

covers the insulation. Use very lightweight materials. It has been determined

that, in real world cooking situations, a 1/8 inch thick Masonite hardboard oven

liner soaked up 20 % of the available heat compared to the 10 % passed by the 4

inches of rice hulls it contained.1 All of this heat loss becomes

unavailable for heating food. Use low thermal mass interior materials. Blackened

or shiny thin gauge sheet metal, black painted corrugated cardboard and

corrugated cardboard with a glued-on facing of aluminum foil (shinier side out)

all give excellent results. The foil-faced cardboard can last 10 years or more

before requiring re-surfacing.

For

lining the inside of the oven, the polyester coated “Aluminum Trim Coil”

sold in roll form by hardware stores works well installed with the dark side

showing (not the white reverse side). Some stores carry only a soft 12

mil type, chocolate brown on one side. Others carry a tougher 19 or 20 mil type

that is sold only in 24 inch by 50 foot rolls. It comes in several colors;

choose the dark brown if you cannot get black. The brown works nearly as well,

but is not optimum. The SOS Sport cooker (www.solarovens.org) uses a black polyester finish, 20-mil

aluminum as the liner because the heavier gauge and stronger alloy holds shape

better. The 20-mil aluminum is stiff enough structurally to form the inner wall

of the cooker without warping. Another liner choice is the less expensive,

shiny, 12 mil “Aluminum Roof Flashing”, which is quite soft. The surface of

this material is not of the highest reflectivity, but it does work pretty well.

It might work a little better if painted black.

For insulation, fiberglass

batt, an old down quilt, new quilt polyester fiber, feathers, rice hulls,

sawdust, crushed newspaper (each full size sheet crumpled to the size of a

lemon) all are effective. Fiberglass batt is recommended only as a last resort.

It sheds irritating fibers and is otherwise unfriendly to work with. It also

compacts severely if it gets wet. Do not use wood ash. It settles over time.

Beware of wool; weevils will eat it. Cotton has durability issues and is not

recommended. Paper mache’ might be OK, one you got it thoroughly dried, but

I’d use 4 inches since it has an R-value of about 2.5 per inch. Multiple

layers of cardboard with aluminum foil adhered shiny side out to both sides (use

diluted with wood glue) gives excellent results. See:

www.backwoodshome.com/articles/radabaugh30.html.

Do

not use polystyrene (Styrofoam) or polyurethane foam board. Heat will melt or

seriously degrade these materials.

One-inch

thick Dow Thermax fiber reinforced polyisocyanurate foam board is an excellent

insulator for solar ovens, but it is not commonly stocked and may be difficult

to obtain in less than semi truckload lots. A roofer’s knife is OK for rough

cuts if the foam board is going to be used as infill for cavities. However, if

you plan to use the foam board structurally and need to make precision cuts you

will find a knife does not “cut it”. Do not use a table saw or skill saw. If

the dust does not get you first, it will clog and burn out the saw motor.

We use a 5-inch diameter pizza cutter from a restaurant supply house

(special order). Even larger is

better – use a 6 or 7 inch garment cutting wheel if you can find one. Run the

blade along the edge of an accurately cut 3/4-inch thick guide board to keep the

cut straight and vertical. These blades have a flat and a beveled side.

Depending on whether you are right handed or left handed, you may need to remove

the blade and flip it over so that the flat side runs against the board, as this

yields a more accurate cut. The more commonly available 4-inch pizza cutter is

OK if you are not using a guide board, but with the board, the hub will bind

against the wood. For angled edges, rip cut a guide board in a table saw to the

desired slant. The writer prefers to make the awkward initial cuts on a 4 x 8

foot sheet on the floor with a sheet of plywood atop the foam so he can kneel on

it without crushing it as he runs the cutter along the guide board. Cut with a

board or piece of sacrificial carpet positioned under the foam so that the

bottom of the blade rides on it. This protects both the blade and the floor

beneath. It helps if the foam is raised about an eighth of an inch above the

board using a sheet of cardboard so that the blade cuts through the foil on the

bottom side of the foam.

The

dust produced in cutting Thermax has fiberglass particles in it. Do not rub

eyes. Use a breathing mask. Wear gloves to protect against foil cuts and glass

penetration into the skin. Vacuum the work area when done.

A

cruder and less accurate method of shaping foam board is to cut the pieces

slightly oversize with a knife, then carefully rasp to the correct dimensions

and angles. This produces loads of noxious dust, however, so perhaps doing this

indoors is not a good idea. Outdoors on a windy day would be a better idea.

Thermax,

being a closed-cell foam, works when wetted. It absorbs very little moisture,

and only on the edges where it is unprotected by the foil facing. This is a

major reason why the Solar Oven Society uses it in the manufacture of their

Sport cooker. See www.solarovens.org.

If

you are not using Thermax, keep the insulation dry. Most types are rendered

ineffective when wet. Some types will compress and not recover shape when dried

(notably fiberglass batt insulation). This causes poorly insulated voids hidden

from sight that can cause poor cooking performance to develop for an oven that

previously was working just fine. Water vapor from cooking food does condense in

the insulation if the oven cavity is not sealed. In Arizona we have never had a

problem with this due to the low humidity and tightly sealed construction of our

ovens. In Minnesota, which has humid summers, crushed newspaper insulation in an

unsealed cooker settled into a pile of paper mush in a single season.

Thermax is rated for temperatures up to 300 F. There is a concern that cookers with external reflectors will get hotter than that this and may degrade the foam insulation. An excellent candidate for insulation that will take the heat is polyester fiber from a fabric store. This is sold in “fiber fill” form (bulk for stuffing pillows) and in batt form (sheets for making quilts). Polyester plastic typically is rated to withstand 425 F. In a 350 deg F oven test that deformed test samples of non-fibered Tuff-R polyisocyanurate, polyester fiber showed no sign of degradation. This inexpensive and easily obtainable material has high loft (does not sag), drains water when wetted, does not rot or deteriorate, is easily handled, produces no harmful fiber “dust”, is easily cut with scissors and is simple to install by stapling or stuffing. When saturated under a faucet, a sample compressed about 50%, then ceased to collapse, suggesting that when using bulk fiber to stuff a cavity that it ought to be compressed 50% to forestall formation of voids. We have not tested the insulation R-value to date, so a thickness of 4 inches is suggested to be on the safe side.

7. Sealing:

For a wall-mounted oven, seal

the oven and pass-through tunnel against rainwater entry. This is particularly

if the cooker is integrated with the structure of the building rather than

simply mounted externally in the fashion of an air conditioner. If condensation

from food or rain entry is not controlled, the water may leak out the bottom of

the cooker and do damage to the building – resulting in peeled plaster, sodden

wallboard, dry rot in framing, etc. Rain must be shed or channeled where it can

do no harm. If the cooker mounts at the end of an extension tunnel projecting

from the house, judiciously placed weep holes may work to provide a drain path

for moisture to exit without getting into the structure of the building. The

seal should also prevent dust and bug infiltration into the oven and into the

house.

Whether wall mounted or

freestanding, the entire inside should be sealed to isolate the cooking space

from the insulation and structure of the oven. This holds moisture emanating

from food within the cooking chamber. Excess moisture can exit the oven via the

vent holes in the door. Sealing the oven chamber forms a barrier to keep

insulation dry. Furthermore this keeps material shed or emitted by the

insulation from getting into the food. This is a general concern for many types

of insulation. Thermax foam board, for example, may shed glass fibers - and it

has been observed when heated to emit a dark film of unknown composition that

deposited on adjacent reflective metal surfaces. We make it a practice to seal

all our oven interiors, regardless of insulation or construction materials.

100 % silicone caulking is an

excellent material as a high temperature, non-toxic, durable, UV impervious,

readily available and inexpensive all purpose sealant and construction adhesive.

It is tough, abrasion resistant, and flexible. Silicone stretches with thermal

expansion without cracking or pulling loose. We use it to solve all sorts of

construction difficulties in building solar ovens, such as sealing foam

surfaces, coating surfaces, forming gaskets in place, filling voids and gluing

parts together. However, as with life in general, “for every solution, there

is a problem”. The stuff is very messy to work with. It is difficult to

apply neatly. It gets all over the place and all over you and your clothes. Your

fingers transfer films of it onto surfaces where you don’t want it.

There, it acts a very good release agent, preventing later adhesion of

paint, glue or tape. Masking tape helps keep it off where it does not belong.

The writer finds that to achieve smooth surfaces, running a finger liberally

lubricated with saliva over the wet caulking gives good results (with practice).

Spit works better than plain water for some reason. It is alleged that a

weak dish washing soap solution will work too. Keep a lot of rags or a roll of

paper towels handy. You will need them.

100% silicone cannot be

painted. For exterior surfaces not subject to high heat, one may prefer to use a

water based latex caulk or a silicone/latex mix to seal joints. Be aware that

neither pure latex not the silicone/latex mixes will stick to 100% silicone, so

making the use of latex types adjacent to pure silicone on an adjoining surface

can be tricky. The latex is paintable, and much easier to apply. It cleans up

with water if smeared where it should not be. The silicone will refuse to be

removed from almost anything if it takes a mind to adhere to it.

Silicone is slow to harden,

especially in dry weather. This can greatly delay construction if you must wait

for it to cure before going on to the next step. It hardens about 1/4 inch in

depth daily at moderate humidity to a “green cure”, and it takes another

week to reach full strength. It takes forever in the summer in the arid

southwest. At our Arizona site in very dry, very hot weather, glazing attached

with silicone was sliding off the cooker several days later due to lack of

moisture in the air to react with the raw silicone. Putting wet pads on the

skinned over surfaces helps, as does putting damp rags inside the oven.

If one reads the labels down

at the hardware store, one discovers that not all silicone sealant is rated by

the FDA as being food safe. We often use whatever 100% silicone sealant we can

find in the local hardware store on the reasonable assumption that the food is

not likely to come in contact with it anyway. We prefer to use Dow Corning 999A,

which is labeled as food safe and which adheres well to all materials used in

solar oven construction - metal, paint, glass, plastic and wood. Other types may

be suitable as well. 999-A, while tough, is still rather soft when cured; other

formulations may be harder and therefore more desirable where exposed to contact

or abrasion. 999A is not readily available – one must go to an industrial

supply house. It comes in several colors. The clear is useful for attaching

glazing or other areas where the caulk should not show. The black is also good

to have on hand to darken areas inside the oven to help absorb sunlight, such as

the cut edge of foam insulation showing through the glazing.

We also keep some white handy, as the need for it arises from time to

time, such as gap filling between two white surfaces.

To make silicone stick truly

reliably, we sometimes use a nasty primer, Dow Corning 1200, which can cause

serious health problems in liquid or vapor form. This stuff is even harder to

get because it is a hazardous material that cannot be shipped via UPS or USPS.

We usually dispense with the 1200 primer and take our chances that most of the

time the silicone sticks well enough without it on a solvent cleaned and perhaps

roughened surface. According to Dow Corning literature, xylol, toluol, and

methyl ethyl ketone solvents (all highly toxic) (but not soap and water)

provide adequate surface preparation, but we have not tried this. Verbally the

Dow Corning tech hotline folk inform us that acetone or isopropyl alcohol works

nearly as well. Also they say that the liquid 1200 primer is toxic because of

the solvents used in it. However the chalky residue left on the dried primed

surface is a perfectly safe silicone carried by the solvents.

If you are using silicone to form a gasket, then you have the opposite problem: how to make it not stick to the sheet of material separating the surfaces during the curing process. For this purpose one uses 10% petroleum jelly dissolved in 90% mineral spirits as a release agent to coat the separator. Just paint it on and allow the solvent to evaporate.

8. Interior:

Raise the floor plate a

little so it does not directly contact the bottom of the oven box. Several ¼ x

¼ inch wood strips cut from square dowels will do the trick. This significantly

reduces heat loss from the primary energy absorber via the oven bottom (the

floor plate is the hottest part of the oven, except for blackened pot lids).

Painting the underside of this sheet with white BBQ paint to lessen losses has

been tried, but it is likely that this did no good since it is reputed that the

heat emissivity (infra red) of a white surface is the same as black. It may help

to have the underside of this plate left as bare silver colored metal to lessen

radiation loss downward toward the insulation, but there are those who claim

this is ineffective. We will be experimenting with some high tech insulating

paint that promises to be effective, according to expert information, to see if

it indeed will help in this location. Contact us for the results.

The upper surface of the

floor must be black (or other very dark color) to absorb sunlight and convert it

into heat.

We

suggest the use of a 0.062 (62-mil) black aluminum floor (best if

“hard” anodized for durability and easy clean up). The heavy aluminum

readily conducts heat to cooking pots. The SOS Sport cooker uses much less

expensive 19-mil polyester coated aluminum trim coil for the floor, which works

well, but eventually will eventually need repainting. Cooked-on food spills tend

to remove the polyester finish. It has not been determined how much better the

thicker aluminum works than the thinner stock in transferring heat from the

floor to the cookware. We intend to settle the issue in side-by-side tests this

summer, comparing 12-mil to 19-mil to 62-mil flooring.

One

can blacken oven surfaces and cookware with BBQ black paint. Black tempura

paint, such as produced by mixing the dry powder with white glue, is used by

some solar cooking practitioners, but others point out that the paint develops a

chalky white surface over time, lessening effectiveness in absorbing sunlight to

produce heat.

Oven

walls should be either dull black or highly reflective. Other dark colors will

work nearly as well. Both dark and shiny surfaces have been found to be equally

effective, but black paint is a lot cheaper than polished sheet metal. Black and

shiny panels can be mixed in the same cooker. White or light colored walls do

not work well; they scatter light back out through the glazing, wasting heat.

9.

Glazing:

The

glazing must be double pane. Single pane does not work for a reflectorless

cooker except in very strong and direct sunlight, and then only if the cooker is

free to be aimed at the sun. It is inappropriate for a reflectorless design

intended for fixed installation in a wall. Triple pane provides no advantage

over double pane.

Retail plastic sheets will

not work satisfactorily as glazing. They will warp, craze, cloud up and

disintegrate. Specialty heat and UV resistant plastic is not readily available.

Ditto for solar rated plastic film, which is virtually impossible to find.

Plastic film is not dog, goat or bird proof.

For

commercially purchased glazing, we use 5/8 inch overall, 3/8 inch spacing, dual

pane, 1/8 inch thick, tempered, clear glass insulated windows with a black or

dark bronze spacer bar separating the two sheets of glass. We specify butyl

sealant for heat resistance. This substance does not out-gas toxic vapor. Such

glazing works very well. It is also costly and heavy. For a 24 by 32 inch

window, we have paid as little as $50 and been quoted as much as $150, so it

pays to shop around. We hear conflicting reports on the use of specialty glass

that admits visible light but blocks the infrared heat radiation from escaping

the oven, with some workers claiming it works better and others saying it

provides no improvement over ordinary clear glass.

Double

pane windows often incorporate a fine diameter metal tube (it looks like a wire)

that extends from a corner of the assembly. The purpose is to allow air to enter

or exit the space between the panes to equalize inside to outside pressure,

depending on the altitude of installation. The standard practice of glaziers

when installing a window in a building is to pinch off this tube to prevent

moisture from entering the space and condensing. Barbara Kerr has solved

condensation problems that were occurring in solar cookers by pinching off this

tube, which she had previously been leaving open.

However the writer does not do this, but rather leaves the tube open, on

the theory that the heating and cooling of the oven creates pressure changes

that ought to be relieved. He does take care to orient the glazing so that the

tube is on the lower (sunward) edge of the cooker so that if moisture does

condense, it can run to the lower end of the glazing space and weep out the

tube.

Regular window glass is

relatively inexpensive but is not as durable for the long haul. The outside pane

will be vulnerable to impact (hailstones). The inside will be vulnerable to heat

stress cracking and being bumped by a pot. If you opt not to use tempered glass,

Joe Radabaugh

http://www.backwoodshome.com/articles/radabaugh30.html

recommends using double

strength rather than single strength window glass. Presumably because it is

thicker, it will hold up better than single strength. His designs, being of the

funnel reflector, 4-panel concentrator type, subject the glazing to quite

considerable heat stress. But then again the glazing size is small, reducing the

tendency to crack. Barbara Kerr counsels the opposite, stating that in her

experience double strength glass, being thicker, had a higher temperature

differential from inside to out, and therefore had a higher tendency to crack

from heat than single pane glass. She says that ¼ inch plate glass, except in

quite small panes, is almost certain to crack.

Perhaps a double strength outer pane and a single strength inner pane

would be the best compromise. Cracks in glass usually do not open to cause a gap

for loss of hot air from the oven, so there is no urgency to make repairs in

them, as they have little effect on oven temperature. If desired, a crack may be

sealed with a thin bead of silicone. Even ordinary clear 3-M “Magic Tape”

has proved to be quite durable for mending glazing.

The glazing must be sealed to

circumvent condensation between the layers. Moisture from cooking food will tend

to fog up this space and block a significant amount of sunlight. This usually

will not be a problem with commercially obtainable insulated glass windows,

which are sealed. If it becomes a problem with home made dual layer glazing, or

even with a commercial window, provide a couple of 1/16-inch diameter vent holes

to the outside air through the spacer between the panes. The first should be in

an upper (north) corner. The other should be in the opposite lower (south)

corner.

Tempered

glass is very strong in some respects. It is quite likely to survive a hard blow

from a baseball bat. However, be very careful not to nick tempered glass. If you

do, you will end up with an expensive pile of glass pebbles. One touch with a

metal screw, and the whole pane will magically crumble before your eyes. Take

pains to carefully pad the glass during handling and storage, paying particular

attention to the edges. If the glass is placed with its weight on a grain of

sand on a hard surface, the effect will have you on the phone ordering

replacement glass.

Glazing

of any type should be installed so that it can be replaced without undue effort

and without damage to the cooker. Making it

removable and also maintaining a moisture seal to protect the insulation space

between the walls from both the weather and oven cooking vapor may require ingenuity.

One solution is to seal the glazing to the rim of the oven with a bead of

silicone inside and out such that a knife blade can be slipped in to cut the

glazing free if need arises.

10.

Dimensions:

Size

counts: make the cooker big enough to cook a full meal for a family on a good

solar day. A big solar oven also will successfully cook smaller amounts under

less than ideal sun conditions. Furthermore, big pots, skillets, cookie sheets

and the like will fit in with room to spare for other cookware. We suggest it be

made big enough to contain two 13 x 19 inch “large” cookie trays. A 20 x 30

inch interior floor space works well; it will require glazing about 24 x 32

inches overall. This much floor space will accommodate 6 “standard” 3-liter

cooking pots (although cooking would be slow, even in strong sunlight, if this

many pots were heavily loaded and all put in at the same time). Most of the

cookers we have made over the years actually have been an inch or so larger than

this.

A freestanding cooker this size will require carrying handles to move it around, particularly if glazed with glass and/or made of plywood, as it will be quite heavy. Some folks put their cooker on a garden cart to move it around (to follow a sunny patch in the yard, for example), and to aim it at the sun.

Suggested

interior dimensions:

Floor:

20 x 30 inches

Back

Wall Height: 14

inches

Front

Wall Height: 5

inches

Door

Width:

26.5 inches

Door

Height:

11.5 inches (to clear 3 liter pots stacked two high)

Walls:

Vertical (not slanted)

Glazing

Angle:

24 degrees (9 inch rise in 20 inches)

The

angle is not critical. Anything between 20 and 30 degrees is acceptable, but

generally cookers have been built with angles between 20 and 25 degrees. Glazing

in the 25 to 30 degree range might be a better idea further north, say 45

degrees north latitude. The 14-inch height allows the upright placement of

gallon-sized jugs across the back of the cooker for water pasteurization.

A door of the recommended

height allows tipping a freestanding oven so that it rests on the rear door to

cook in low angle sunlight. This presents a steeply slanted glazing surface to

intercept most of the available light. For this position, the cooker is loaded

by placing pots on the opened door, then raising (rotating) the entire cooker up

with the door laying flat. The 11.5

inch height will clear two “standard” 3 liter pots (shown as "Three-pound

roaster" at:

http://65.108.108.197/catalog/supplies-c-2.html?osCsid=5cee5dfca0fbb80b13a6ab53dbc58f4b)

stacked one atop the other with the bottom of the upper one acting as the lid of

the lower one. The suggested door width will accommodate two such stacks,

allowing a total of four pots in the oven in this position.

You

may choose to increase the floor size some. The heights are well proven in

practice, and you change them at your peril. Too low and your pots may not fit.

Too high and the effectiveness of heat transfer into the food may suffer.

11.

Installation Guidelines:

The

floor of the pass-through tunnel should be set such that the oven floor is at

elbow height. Assuming the door opens downward onto the pass-through floor, the

upper surface of the door then will also be at the oven floor height, or close

to it. This is about 42 inches for a person 5 feet 6 inches in height. The

tunnel opening itself ought to be something like 18 inches in height to allow

adequate access and visibility into the oven. The tunnel walls ought to be

insulated to prevent heat loss from the home in winter or heat infiltration into

the home in summer.

One

should consider installing a door at the kitchen (indoor) end of the tunnel.

This would be a second door in addition to the oven door proper at the far end

of the tunnel. The kitchen door may

open downward 90 degrees to form a shelf, or fold 180 degrees in any direction

against the wall to allow closer approach to the oven. The kitchen door provides

a barrier against loss of room heat via the pass-through tunnel walls – a

potential problem in winter. Ditto for unwanted heat infiltration from outside

in the summer. This consideration is significant if the tunnel walls are not

insulated. Another benefit of having doors at both ends of the tunnel is that

the space between them is often at a good temperature for raising bread dough.

For security against intruders gaining entry via the cooker, say by removing the

glazing, one might consider making this kitchen door stout and securely

lockable. See:

One

should consider installing a door at the kitchen (indoor) end of the tunnel.

This would be a second door in addition to the oven door proper at the far end

of the tunnel. The kitchen door may

open downward 90 degrees to form a shelf, or fold 180 degrees in any direction

against the wall to allow closer approach to the oven. The kitchen door provides

a barrier against loss of room heat via the pass-through tunnel walls – a

potential problem in winter. Ditto for unwanted heat infiltration from outside

in the summer. This consideration is significant if the tunnel walls are not

insulated. Another benefit of having doors at both ends of the tunnel is that

the space between them is often at a good temperature for raising bread dough.

For security against intruders gaining entry via the cooker, say by removing the

glazing, one might consider making this kitchen door stout and securely

lockable. See:

On

a southerly facing wall oriented somewhat to east or west, always slant the cooker

relative to the wall so that it faces due south.

For

a house not oriented on a true north-south / east-west axis, location of the

cooker on the most southerly facing wall as close as practical to the

southernmost corner will give good results. In this position, the cooker will

tend not to suffer shading in the afternoon either from the roof overhang or

from the house walls.

For a cooker mounted in a

true south-facing wall, installing it close to the east or west corner will

extend cooking time, particularly in summer when the sun rises and sets

considerably north of the due east-west axis. For example if mounted at the west

corner, it will catch late day sun for a longer time, particularly if fitted

with a reflector which can be brought in to play to scoop in the low angle light

until the sun hits the horizon. As in the case for all fixed mount cookers, this

optional reflector would have to be hinged or removable to keep it from getting

in the way during portions of the day.

The

cooker may be installed flush against the house if there are no eaves. However,

if the house does have eaves, one must space the cooker out from the

exterior of the house far enough to clear the shadow of the roof overhang. This

means that the pass-through tunnel must extend beyond the exterior wall of the

house to reach the rear of the cooker. The length of this projection will be

greater, the closer to equator the cooker is installed. The worst case will be

at solar noon at the summer equinox (June 22 in the northern hemisphere.)

Assuming the cooker is installed in vertical rectilinear wall oriented due south, the following formula applies to determine how far the top corner (northernmost edge) of the glazing must be positioned beyond the exterior wall of the house, given the latitude, the depth of roof overhang and the distance of the top corner of the glazing below the roof overhang.

L = latitude

F

= latitude factor from table

R

= roof overhang (horizontal distance from eve edge to wall)

G=

glazing distance below the roof overhang (vertical distance from horizontal plane

of eave edge to horizontal plane of topmost edge of glazing.)

P = projection of

pass-through (distance from house exterior wall surface to edge of glazing).

P = R – F x G

This equation is presented below as such calculations appear on tax forms.

1. Enter latitude degrees 1.__________

2.

Enter factor F from the table below

2.__________

3.

Enter glazing distance G

3.__________

4.

Enter roof overhang R

4.__________

5.

Multiply line 2 times line 3 and enter the result here

5 .__________

6.

If line 5 is greater than line 4, enter zero on line 8

7.

If line 5 is less than line 4, subtract line 5 from line 4

and

enter the result on line 8

8.

Pass-through projection distance P

8. __________

Latitude (L) Factor (F) Latitude (L) Factor (F)

26

.004

35

.148

27

.020

36

.164

28

.036

37

.180

29

.052

38

.196

30

.068

39

.212

31

.084

40

.228

32

.100

41

.244

33

.116

42

.260

34

.132

or:

F = (L

– 26) x .016 + .004

and:

P = R – ((L – 26) x 0.016 + .004) x G

(for

the more mathematically minded)

12.

Reflectors:

The slant-faced box cooker,

of which the Solar Wall Oven is an example, is intended to work well without

reflectors. Despite that, one is tempted to add reflectors to “soup up” the

performance beyond the original design objectives. Primarily, reflectors added

to either freestanding or wall mounted cookers will allow cooking in less than

ideal sun conditions: partial cloudiness or low sun angle (high latitudes,

winter, early or late in day). They also yield faster cooking and pasteurization

under any sun conditions, allowing an oven to cook significantly more food or

purify much more water in a day. An important consideration here is that cooking

with reflectors extends the number of hours for cooking from earlier in the

morning to later in the afternoon. This allows use of the sun before the clouds

come in or food to be kept hot for a later dinner. It also allows more effective

use of low angle sunlight during winter months to increase cooking power. The

desirability of enhancing heat collection using reflectors increases with cold

weather, high altitude, high latitudes, short winter days, wind and heavy loads

of food – all factors that impede the cooking process. The penalty for using

reflectors is greater complexity of construction, unsightly appearance,

vulnerability to wind (breaking the reflector panels or overturning a

freestanding cooker), the need for frequent re-aiming, the need to manage the

reflector angles, personal and neighborhood glare nuisance, the danger of

overcooking or burning food, and concern for damaging the oven due to

overheating. For a through-the-wall installation, reflectors generally will

require the cook to go outside to adjust the reflectors occasionally, negating

some of the convenience having a built-in solar cooker. Overheating is of

particular concern if you elect to use Thermax polyisocyanurate foam panels for

insulation – you are pushing this material to it’s limit when the oven

reaches 300 deg F, which can happen without reflectors with an empty oven in full sun. Reflectors can raise the oven temperature to 350 deg F, making

one worry about damaging the insulation, or otherwise shortening the life of the

cooker. Reflectors may also damage

plastic glazing due to overheating.

One way to approach the

reflector issue is to construct the oven without reflector(s), then add them

later if the cooking situation seems to warrant it. For high efficiency,

slant-faced, box cookers such as the Solar Wall Oven or the Sport, the writer

views reflectors as an option for occasional use when needed, but to be taken

off the cooker under good sun conditions. He may, for example, get the food up

to cooking temperature in the early part of the day, then remove the reflectors

to prevent overheating problems for the balance of the day. Barbara Kerr, on the

other hand, considers putting reflectors on a Solar Wall Oven to be too much of

a nuisance to be bothered with, whether freestanding of wall mounted.

The

type of reflector to use depends on whether or not the oven can be turned to aim

at the sun and whether or not the oven is intended for use also as a retained

heat “haybox” type cooker. We need to consider through-the-wall mounted and

freestanding cookers separately.

For

through-wall-installations in temperate latitudes,

the Kerr-Cole Center has come up with an effective design we have dubbed the

“3-panel adjustable reflector”. See Figure 1. The reflecting panels are

hinged for repositioning to collect sunlight to good advantage all day long.

Compared to a freestanding cooker, a cooker installed in a wall with a 3-panel

adjustable reflector has the advantage of not needing turning to face the sun.

Only a panel angle adjustment three times daily is required. It also has the

advantage of having available the solid structure of the building to brace the

panels against the wind. This overcomes a couple of the drawbacks of reflectors,

the need for frequent re-aiming and the vulnerability to wind. The inward slant

of the panels also means that nuisance glare is eliminated. The reflector can be

mounted to the house and cooker supports rather than the cooker itself,

simplifying oven construction and installation considerations. An adjustable

3-panel reflector does not need much attention. An initial setting in the

morning followed by a mid day positioning followed by an afternoon positioning

will allow good heat collection all day long. A clever person might even devise

a way to adjust the panels from indoors, eliminating the need to go outdoors.

Figure

1:

Solar Wall Oven with Experimental 3-Panel Reflector. A south facing

installation is depicted in late day configuration to collect low angle sunlight

from the southwest in winter. West panel extended

fully. East panel brought in fully. The front strut is a fixed length, tensioned

rod to rigidly brace the fixed rear reflector perpendicular to glazing. The

adjustable length tensioned rod for holding the west panel in position is also

shown. A third strut (not shown) is used to hold the east panel when it is not

fully brought in. In mid day the east and west panels are partially brought in.

In morning the east panel would be fully extended and the west panel would be

fully brought in.

This design was successfully used to collect sunlight with the sun close to the horizon at 35 degrees latitude on a cooker with 20 degree slanted glazing. The dimensions and angles, as shown in Figure 2, were a "cut and shoot" quickie design. They were not mathematically determined and no claim is made regarding optimal performance for the given latitude and glazing angle.

The struts for the reflector panels may attach to the oven as shown, or may attach to the house or oven mounting structure. As shown, the rods ought to be tensioned - that is a cord or an elastic band should strongly pull the panel toward the oven attachment point of the rod. The cord should not fasten to the rod itself. A similar arrangement would work if the rods attached to the house. One half inch diameter wood dowels serve well as struts.

Figure 2: 3-Panel

Reflector for Fixed Installation of Solar Wall Oven.

At

our 35 degree latitude, we have found that this 3-panel adjustable reflector

works very well in the fall, winter and spring seasons for a due-south, fixed

aim cooker in terms of power collection, length of cooking time and simplicity

of use. It is not effective in the

summer, but neither is it needed in the months of long days, hot weather and

high angle sun. The cooking capacity of the basic Solar Wall Oven (i.e., without

reflectors) reaches a maximum in the weeks before and after the summer solstice

(June 22). The reflector gives a boost when it is needed, in the cold, short,

low sun angle, winter months. From the fall equinox (Sept 22) through winter to

the spring equinox (March 22) effective heat collection would be from sunrise to

sunset. At the equinoxes the reflectors will be effective 12 hours from 6 AM to

6PM, yielding the longest cooking times of the year.

After the spring equinox the

time duration of effective heat collection of the reflectors progressively

diminishes. The reflectors will remain effective until perhaps 6 weeks after the

spring equinox (until May 10). This loss of effectivity of the reflectors occurs

because the sun rises and sets north of the east-west axis during the summer

half of the year, with the result that the house blocks light early and late in

the day. In the fall, the reflector will become effective again about 6 weeks

before the fall equinox (until Aug 10). The duration of effective heat

collection added bys the reflectors progressively increases as the fall equinox

approaches.

In the intervening 3 summer

months between May 10 and Aug 10 the reflector does not help for three reasons.

First, until about 8 AM the house will block the sun. Second, by the time it

reaches due east at about 8 AM and can illuminate the cooker; the sun will be so

high in the sky that the reflector can collect little additional light. Third,

toward noon the reflector will generally be in the way and actually shade the

glazing. As the sun travels toward the west in the afternoon the reflector will

be ineffective in the same way it was in the morning. Conclusion: In the

interval between May 10 and Aug 10, the reflector should be either removed or

folded back out of the way.

For

an in-wall installation in the tropics

(possible in a domed or vaulted structure only) (see discussion in Section 3),

the reflector design must be different – the adjustable 3-panel configuration

will not work. A single panel will work, slanted inward to catch low angle light

for horizontal or near horizontal glazing. It should be removable so that it can

be placed on the either the east or west lip of the cooker to collect light

early and late in the day. Mid day the sun will be high overhead, and the

reflector will not be needed to redirect low angle sunlight; it should be

entirely removed until evening to keep it from shading the glazing. Observe that

near the equator a cooker with an eastward facing reflector will cook breakfast.

This is an important consideration for architects and designers of equatorial

dome shaped homes.

Instead

of a single reflector that the cook moves from the east or west lip of the

cooker, one may hinge reflectors to the east and west lips of a flat glazed

tropical cooker. By adjusting the

angles of the panels to morning, mid day and evening positions, this

two-reflector design can be effective all during the day in a fashion similar to

the 3-panel reflector for temperate latitudes. This type of design has the

advantage of collecting extra light in less than full sun weather

such as on a pertly cloudy day.

For

a freestanding cooker,

there are two common choices for reflectors, the classic 1-panel rear mounted

reflector and the 4-panel “funnel” type. These types each have their

advantages and disadvantages for a freestanding cooker. Neither will work for a

fixed mount installation, as they both require the cooker to turn to face the

sun.

The

1-panel reflector has a major advantage

in that, if the reflector panel is made of foam insulation board, it can be

folded down to insulate the glazing (the major source of heat loss from the

cooker). This allows use of the

cooker as a retained heat box (“haybox”) to keep food cooking when the sun

disappears, to keep food warm until dinnertime, or to lessen power requirements

if auxiliary heat (see Section 13) is employed to use the cooker as a non-solar

oven. A one panel cooker not only needs occasional re aiming to face the sun,

but it also requires the reflector angle to be periodically adjusted to bounce

the sunlight into the oven space. A cooker with a single panel reflector can

collect heat with the sun very low in the sky. The cooker need not be flipped to

lie on its back to catch low angle sunlight. The need to do this when using a 4

panel reflector creates an inconvenience if there is food cooking in the oven,

as all the cookware must be removed to get the cooker from “summer” to

”winter” position, and probably not all of the cookware will fit back in due

to lessened floor space. A conventional box cooker with a single reflector is

shown at:

The 4-panel reflector

requires an auxiliary insulating blanket or panel to achieve “haybox” heat

retention. There are no elevation angle adjustment difficulties with this type,

but it cannot collect low angle sun with the cooker resting normally on its

bottom. The cooker must be tipped forward on its front (see Section 11) to its high

glazing angle “winter” position to collect light from near the horizon, and

it is likely the lowermost reflector will interfere with placement in this

position unless the cooker is put on a stand. This type reflector on the SOS

Sport cooker has been observed to give excellent results (temperature exceeding

220 deg F) in Minnesota (45 degrees north latitude), in December, cooker resting

on a snow bank in “winter” position, with a high outdoor temperature of –3

deg F for the day. A conventional box cooker with four reflectors is shown at:

13. Auxiliary Heat:

In the absence of sun, a

200-watt auxiliary heater (such as an incandescent light bulb installed in the

oven cavity) will keep food hot enough to prevent incubation of food spoilage

microorganisms before dinner is served. If one places insulation (an old quilt

for example) over the glazing, only 100 watts is required. Use a thermometer to

verify that the oven remains 150 deg F or above. Foods held more than 2 or 3

hours in the incubation temperature range between 50 deg F and 150 deg F may

suffer serious spoilage. Toxins from bacteria such as botulism (which is not

totally destroyed below 240 deg F) can cause fatal food poisoning. Foods in the

danger zone of temperature must either be cooled below 50 deg F or reheated

above 150 deg F to inactivate microorganisms. Food that has slowly cooled from

cooking temperatures down through the danger zone over a period of 2 or 3 hours

to below 50 deg F should not be re-warmed later to again reside in the danger

zone, but rather should either be eaten cold or brought to cooking temperature

above 180 deg F. The point is that the total time the food remains at

incubation temperature over more than one episode of cooling and warming should

not exceed 2 or 3 hours before the food is brought to cooking temperature to

sanitize it.

With 200 watts and the glazing covered with insulation one may continue or even initiate the cooking process. The writer slowly cooks food this way on occasion, using the Solar Wall Oven as a sort of giant crock-pot. This is a good way to cook the beans overnight for the next day’s chili if sufficient electrical power is available to keep the heater on at night. The heater should be thermostatted to prevent overheating. One must protect against inadvertently leaving the heater on with the oven in full sunlight, particularly if the reflectors have not been removed.

References:

1.

Paul A. Funk and William F. Wilcke, University

of Minnesota Dept. of Agricultural Engineering, 1390 Eckles Ave., St. Paul MN

55108, Draft of presentation to the 1992 World Conference on Solar Cooking, “A

Solar Box Cooker for Mass Production in East Africa”, Based

on Paul Funk’s master’s thesis at U. MN, Dec. 1992, “Analysis

of a Solar Box Cooker for East Africa”

This

article analyses where the solar energy that enters a cooker goes in the time it

takes to get the food to cooking temperature: how much heats the food, how much

heats the oven box, how much escapes through the sides and bottom and how much

escapes back out the glazing.

2.

Bevill Packer, Chapter 10: APT

solarware, “Appropriate Paper-Based Technology (APT, A Manual)”,Intermediate

Technology Publications Ltd.,103-105 Southampton Row, London WC1B 4HH, UK, ISBN

1 85339 268 5

Sources:

1.

Material for reflectors:

Highly

reflective polished metal surfaced plastic film may be obtained from Nielsen

Enterprises: http://www.mirrorsheeting.com/.

This material is suitable for external reflectors. Our experience with using

plastic reflecting film inside the cooker is that it gets very brittle and

fragile after a year or so.

2.

Black

paint:

For both oven

interiors and cookware we use a 1200 deg F BBQ black paint such as Rust-Oleum

High Heat enamel, UPC 0 20066 77788 3, also designated as (BAR-B-Q-BLACK 7778).

When used on cookware, it will adhere better (last longer before requiring

repainting) if the surface is roughed up. We scour glass vessels with sand. One

might wire brush a metal pot. Do not allow paint to lap into the interior of the

pot.